Team Cerebrus comes second with its janitorial assistant at the ARTPARK-organised robotics challenge while Team Lumos wins third place in the Open Cloud Table Organization Challenge at ICRA 2022.

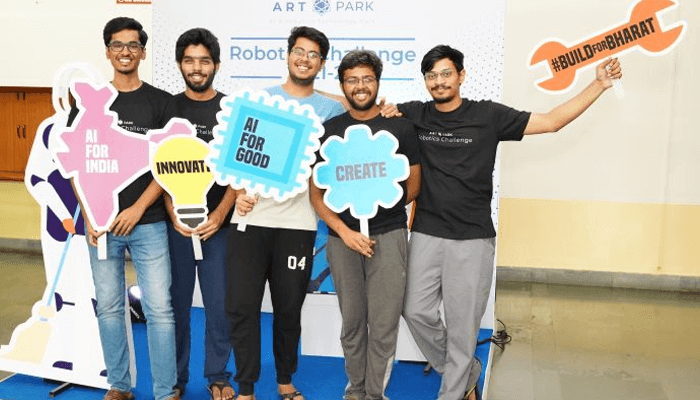

At the recently concluded Robotics Challenge held by Bangalore-based not-for-profit foundation, AI and Robotics Technology Park (ARTPARK) at IISc, IIITH’s students competed with 133 other teams and walked away in second place winning Rs 2.5 lacs in cash. Deriving inspiration from challenges posed to sanitation workers through surface transmission of Covid-19 virus, the competition sought to automate typical cleaning tasks in a washroom with the creation of a janitorial robot. The tasks included picking up trash such as tissue paper and small paper cups that may be on the floor followed by cleaning the washbasin and the countertop with a sanitizing liquid. Teams were scored based on time required to complete the tasks, minimal collisions, degree of finesse demonstrated by the robot such as countertop cleaning without toppling the soap dispenser and other objects, the amount of hardware required for the solution and so on.

Unique Features

The competition which officially kicked off in March 2021 shortlisted 29 design proposals from across the country for a simulation round with the proposed robot performing the said tasks. From these 29 teams, 4 teams were shortlisted for the grand finale where each team was given a budget of Rs 4 lacs to build the robot.

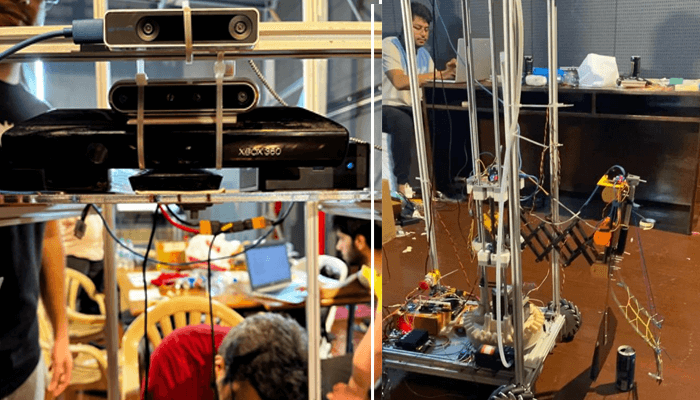

IIITH team Cerebrus was led by Suraj Bonagiri, Ph.D scholar as well as founder of a drone startup, Arka Aerospace, and included Vedant Mundheda, Karan Mirakhor, Rahul Kashyap, Sreeharsha Paruhuri and Karnik Ram. Speaking of what made their submission stand out, Suraj says, “Every team had amazing and unique designs but IIITH’s submission stood out in 2 aspects: Firstly our solution was a pure vision-based perception stack. What it means is that for robots to perceive the world and navigate autonomously, sensors like LIDARS, RADARS, and cameras are typically used. Our robot performed all the required tasks just by using camera-based techniques which is considered quite challenging. Also, as cameras are significantly cheaper, the overall cost of the robot came down substantially. Secondly, we used pose and size-agnostic end effectors. They are basically grippers which are part of a robotic arm that performs grasping of objects. We developed a gripper that could grasp any sized object in any orientation with zero slippage once grasped. More importantly, it costs only Rs 150 to design the end effector.”

The Complete Pipeline

For Prof. Madhava Krishna, head of the Robotics Research Centre, the win is a matter of pride. “This is a hardcore robot building, sensor instrumentation followed by algorithm development pipeline,” he says. Calling it a first for the Robotics Centre, he elaborates, “We’re known more for our research focus and industry-led collaboration. To come out in flying colours in a competition where the emphasis is on engineering, design, electronics and hardware is worth celebrating. Plus, many of the students involved are from ECE, ECD or MS in ECE”. Creating a full-fledged product such as a robot from scratch involves designing, building and integration of various sub-systems. “But do they operate as expected? Never!”, exclaims Suraj. “Especially during the initial stages, each sub-system malfunctions in its own way despite careful consideration of the design. These problems can easily overwhelm and break the spirit of a robotics engineer. But our team has done a fantastic job by being very patient and skillful in debugging and hosing down these fires.” Another challenge that the team successfully surmounted was the constant attrition in the composition of the team. “Since the competition lasted over a year, some members graduated and left the institute. That posed certain anxiety about who would take up their role next,’ admits Suraj.

Benchmark for Grasping

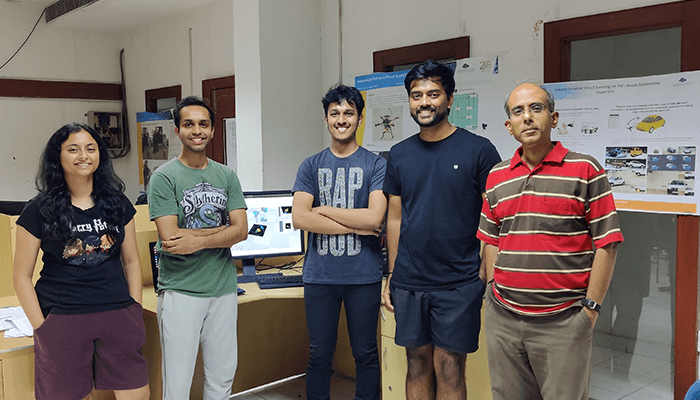

In another proud moment for RRC, team Lumos comprising Aditya Agarwal, Bipasha Sen, Vishal Reddy Mandadi and Shankara Narayanan came third winning 1,000 USD in an international robotics competition organized by the IEEE International Conference on Robotics and Automation (ICRA) 2022. The team, which was mentored by Prof. Krishna, in collaboration with TCS Research India, vied with 24 other top Robotics institutes from over the world in the Open Cloud Robot Table Organisation Challenge (OCRTOC). A significant part of robotic research involves robot grasping and manipulation. Manipulation goes beyond just picking up, and holding objects. The quest is on to create human-like dexterous arms and hands that are capable of performing a variety of tasks like throwing, tapping, sliding, stacking and and so on.

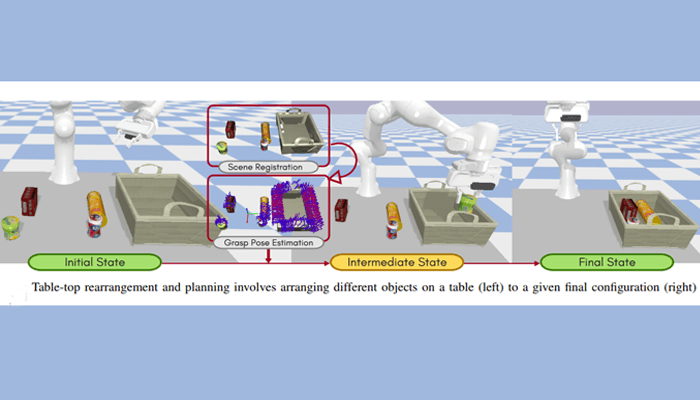

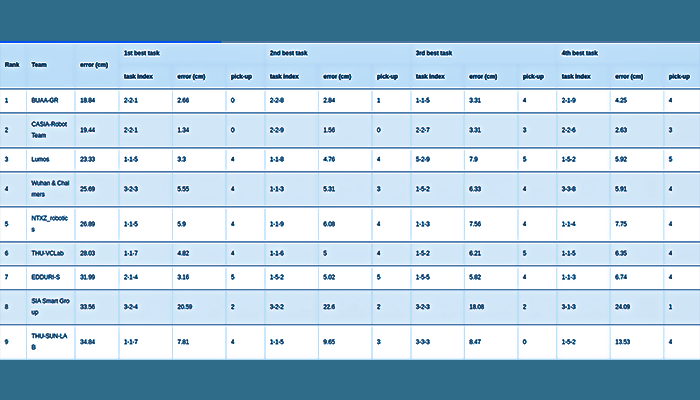

The OCRTOC is a cloud-based benchmark for robotic grasping and manipulation with a special focus on rearranging and organizing table tasks – considered essential for service robots in warehouse automation, in the dining industry, and for assisting humans in performing dirty, dull, distant, dangerous, or repetitive jobs. According to the challenge organisers, there is a need for breakthrough technology to make it mature. Each participating team had access to a simulation setup – which is an exact replica of a real robot setup – consisting of a 6DOF Franka Panda robot arm with a 3D real-sense camera attached to its wrist, a stationary RGB-D Kinect camera, and several objects placed on a tabletop. The goal was to manoeuvre the robot arm in complex scenes or to solve multiple tasks of varying complexity, such as stacking objects, picking and placing objects in clutter, swapping objects, etc., with as little error as possible.

Superior Stacking and Swapping

Team Lumos states that they improved upon the baseline solution provided by the OCRTOC team in a number of ways including improving the manner in which the robot arm grabbed objects, smoothening the overall movement of the arm itself, improving the 3D reconstruction of the tabletop scene and building a full-blown planning module from scratch that could handle cases the existing state-of-the-art planners couldn’t, such as stacking and swapping objects. According to Aditya, “Building an end-to-end pipeline that can be generalized to multiple scenes was challenging since the pipeline involved multiple moving parts, including deep learning, computer vision, and robot planning stacks”. The joy of securing a podium finish notwithstanding, the team found that the mere participation in the challenge itself helped them in identifying critical challenges in the area and in formulating several research directions. “Robust 6D object pose estimation, inpainting an incomplete 3D pointcloud registration and exploring synergies between pushing and grasping objects in scenes involving clutter are some challenges in Robotics,” says Bipasha, adding that there is now an active group working on these research areas under the guidance of Prof Krishna and collaborators.

Next post